Innovation, Design and R&D Capacities

The Group has industry-leading R&D centers located in Ningbo and Germany, with full capacity of parallel design and development with OEM customers. The Group has built a highly experienced R&D team of more than 500 staff and 3 moulding design and manufacture facilities in Germany and Ningbo respectively, focusing on the design and manufacturing of automotive interior and exterior parts moulds.

Synchronous Designing Capacity with Customers

With full capacity jointly developed with OEM customers, the Group adopts advanced designing and auxiliary tools, including UG, CATIA and CAE to increase the accuracy and shorten the development cycle. The Group utilizes analysis softwares like MOLDFLOW to verify design of different parts, assess the feasibility of moulds R&D proposal and improve the design proposals accordingly.

New Product Lifecycle Management System

The Group has implemented overall PLM system since 2015, established a complete, stable and practical quality management platform for delivering R&D projects, and standardized project processes and improved the project management capacity within the Group.

Strong Development and Production Capabilities of moulds and toolings

The Group has 2 moulds R&D and manufacturing facilities respectively in Xiangshan, Ningbo and Germany, with multiple moulding manufacturing machines, Italian PARPAS five-axis manufacturing center, Japanese OKUMA five-axis manufacturing center, Global five-axis digging and CMM measuring center, which guarantees the manufacturing capacity of high-end, precision and high-tech moulds. The Group has established deep technical collaboration with advanced moulding companies in Germany, Switzerland, etc. The Group has the capacity of developing over 60 new projects and manufacturing 300 moulds annually.

Strong Production Capabilities

With advanced machines, experienced production techniques, complete manufacturing processes, pleasant working environment and well-trained staff and teams, the Group continuously adopts the most advanced production equipment, process and techniques from all over the world. The Group fully utilizes smart manufacturing techniques, interconnected machines inspection technology, as well as advanced software systems such as MES, WMS and MRP, to support our highly efficient and automated manufacturing management.

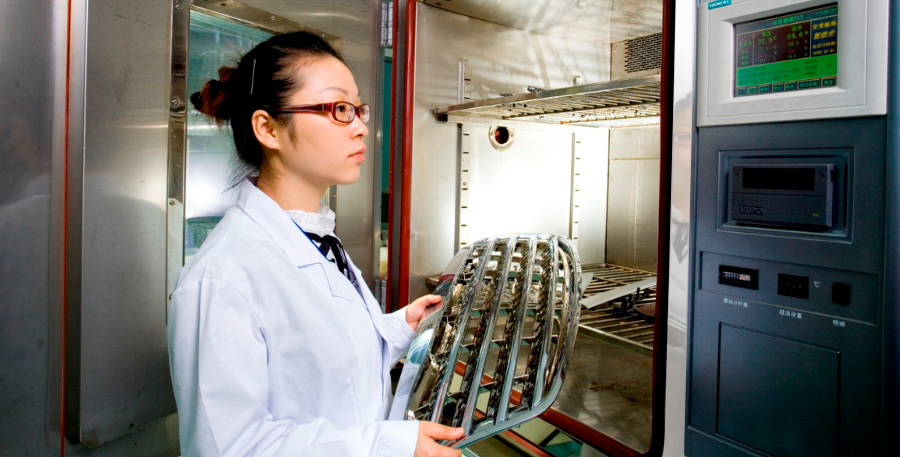

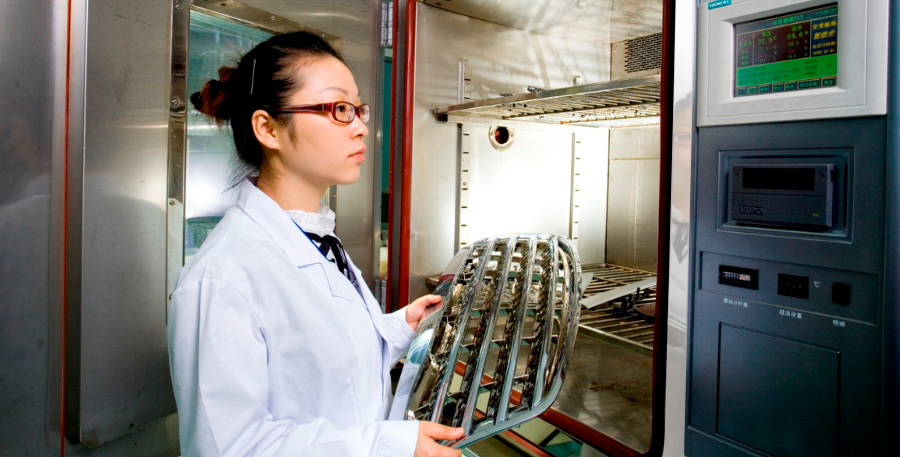

Quality Assurance Capacities

Following the quality guidance of ‘Customer-Oriented and Always Exceed Customer Expectation’, the Group has passed all quality-related assessments, including IATF16949, CCC, ISO14000 and OSHS0 18000.。

The Group has established its own laboratory center with multiple world-leading testing and trial equipment; thus providing assurance for high product quality and good customer feedback.

Well-equipped laboratories for conducting products’ functionality experiments, raw material experiments, appearance and size inspections, providing assurance on its project development.